Observatory Command Center

(OCC)

In May 2016 my wife Sachiko provided me with a grant

to permit me to purchase a cargo trailer to keep at my Shady Grove (“swamp”)

observatory. This would be great as I could put a heater in it in winter and image

from the comfort of a heated room. After looking at various web sites for

ordering custom cargo trailers I settled on Diamond Cargo Trailers (since they

had a great web site for custom options). I decided on the following trailer

and options:

1. 7ft wide x 12ft long single axel trailer. This was

1,500 lbs (the towing limit of my Subaru Forester),

and 6ft wide seemed a little narrow. It has a V-nose, so there is another 2ft

of area (triangle shaped) in the front.

2. Additional 6” of height (80” high inside). I am 6’2”

and did not want to crouch or bump my head since the standard height is about

6’2”.

3. Fully insulated (ceiling, walls & floor).

4. Rear doors instead of ramp

5. 30 amp electrical package (breaker, 2 fluorescent

lights, 2 outlest, 25ft power cord)

6. Lots of windows to avoid claustrophobia. 2 windows

30”x30” each side above axels. 2 windows 30”x15” (one on each side of the front

V-nose, so as to monitor the telescope. 30”x15” window in side door.

7. 2 rear jack supports (more about these below)

8. Silver color

I ordered the trailer May 4 and picked it up June

17. Prior to pick up I had a lot of anxiety about the trailer being stolen. I

did not think about it much until my wife Sachiko said it might happen. Then I

went online and found out that it was pretty common for trailers to be stolen

since the VIN numbers are often just on paper stickers. Once these are removed

the trailer can be registered as a “homebuilt” trailer and assigned a new VIN

number. I purchased two locking wheel chocks, a hitch receiver lock, locking

lug nuts, and the largest chain I could find (to lock the frame to the power

pole). I also prepared the site by cementing two posts at the edges of the

access road and putting a chain across it.

I went on YouTube to look up trailer theft, and it turns out that each

of these devices can be defeated and all they do is slow down a determined

thief. In combination they might occupy about 30 minutes of a thief’s time –

but the trailer is unattended on the property some times for as long as 3-4

weeks. About 5 days before the trailer was due to be picked up I had a dream

about a possible effective solution. It involved pouring a steel reinforced

concrete pillar through the “V” of the hitch. To get the trailer out of this

post either it would have to be jackhammered (steel reinforced concrete), or

the entire trailer would need to be lifted 4 feet in the air and moved, or the

hitch would have to be cut off. Thus, while it is not purely escape proof, this

solution seemed pretty robust. About 4 days before the trailer was due to be

picked up I rented a powered auger and sunk an 8” Sonotube

carboard form and three ½” rebar rods (4’ long) and

poured a 3’ deep concrete footing. I left 6” of the rebar exposed for wiring to

another set of three rebar.

I then picked up the trailer. It was an eventful

day…

I left home at 6:00 am so as to hopefully get the

trailer at the swamp before the afternoon rains (more about this later…). The

trailer manufacturer is in Georgia (about 2 ½ hours away) and they opened at

9:00. The plan was to gas up in Tallahassee, then gas up in Georgia, pick up

the trailer, and drive directly back down to the swamp with a full tank of gas.

Thus, I would not have to deal with driving the trailer into a gas station

before getting to the swamp (probably not a big deal, but I did not want to

screw up by smacking the roof of the trailer on some gas station awning).

I got to the trailer manufacturer around 9:00 and

filled out the purchase paperwork. The representative asked me if I wanted to

buy a spare tire (for $100). Since I was not planning to drive the trailer

around – just drive the 100 miles to the swamp and part it eternally, I

declined. When I hooked up the trailer to my car the guy helping me asked me if

I was going to get a spare tire – to which I replied “no”. The paperwork with

the trailer said that after 50-100 miles the tire pressure and lug nuts should

be checked. Since I was driving 100 miles I figured no need to do that.

The trailer looked great! I had never towed anything

before and it was clear that the trailer was a significant load for the Subaru.

This load seemed to be a combination of the increased wind resistance and

weight. One thing I did not count on was a reduced mileage when towing the

trailer. Normally on the highway the Subaru gets about 26 miles per gallon;

however, upon check the mileage when towing it was more like 12. A calculation

of the gas tank capacity indicated I still should be able to get to the swamp

without refueling; however, it reminded me a lot of those old war movies where

a plane that is all shot up and leaking fuel is attempting to get back to base.

On the drive back down from Georgia I kept away from

freeways and took country roads where there was minimal traffic and I could

drive 50 mph without pissing anyone off too badly. After driving about 15 miles

or so I made a left turn and hit a bump. After this there was a strange

vibration, so I pulled off the road, got out and looked around. I could not see

any obvious problem so I decided to drive on. About another 10 miles down the

road a car pulled alongside of me and motioned to me to pull over. These

friendly folk said one of the rear support jacks was extended downward. Sure

enough it was extended – apparently the factory did not lock it in the “up”

position and the bump knocked it down. The footing of the jack was now bent due

to striking the road (thus, the initial vibration). For a while, I am sad to

say, it eluded me how to release the lock and retract the jack (but I figured

it out eventually). I was lucky that the rear corner of the trailer was not

ripped off. Lesson #1: double check the locked and retracted position of the

rear support jacks. Here is an image of the offending jack:

Back on the road things were going well and the

miles were winding down. I remember thinking that most disasters seem to occur

right at the end of such adventures, right when things are going well and

success is in sight. Sure enough, only 7 miles from the swamp (i.e., after

driving about 93 of 100 miles) there was another vibration. I looked in my

rearview mirror and it looked like there was a problem with the driver’s side

tire on the trailer. I initially refused to believe it might be a flat; but,

sadly, it was. I pulled over in some people’s driveway and got out. Sure

enough, one of the tires on the trailer was flat. Not only was it flat but the

entire sidewall was destroyed. I could not believe that after only 93 miles the

tire had decided to disintegrate. I now understood why the trailer manufacturer

was pushing the sale of a spare tire. I decided that they provide the cheapest

possible tires that can be purchased and 100 miles was really pushing the

envelope on its lifespan. At that moment I wished I had bought a spare tire.

But, what to do? I figured the jack on the Subaru would work on the trailer

since it was a simple scissor jack – and it did. I then wondered if the Subaru

spare would fit on the trailer (since they were both 5 bolt patterns). Sadly,

it did not (the trailer bolt pattern is a little larger) – why the hell they

can’t standardize a wheel bolt pattern I will never know. I decided to unhitch

the trailer, try to lock it up (with a hitch receiver lock) and drive the spare

tire to the nearest tire dealing and see if I could get a new one installed. I

left the trailer, sans wheel, on the scissor jack and drove about 20 miles to

Perry, Florida and the nearest tire dealer. For $65 I got another tire mounted.

Back to the trailer, I then bolted it on, backed up the hitch (using the Subaru

rear view camera to great effect). And took off down the road again. Here is

the replacement tire on the trailer:

Driving down the road I began to think that

if one tire lasted only 93 miles, what can I expect of the other tire? I drove

*really* slowly, white knuckles clenching the wheel, for the remaining few

miles. Since it was now afternoon, as I approached the swamp it started to

rain, and then lightning shot down all over the place (but mostly in the

direction of where I was headed). I thus pulled into my property in the swamp

(which is a large cleared area) paranoid of being hit by lightning, and also

being pelted by rain. However, after a short time, the weather seemed to clear

and so I took the next step of lining up the hitch opening over the 8” cement Sonotube in the ground. One thing I did not think about was

whether the opening of the hitch A-frame was larger than 8” (and thus the Sonotube could fit through it). Turns out, it is exactly

8”. This initially seemed like good news; however, the bad news was that the

hitch had to be PRECISELY centered above the Sonotube

for the planned above-ground extension to fit. It only took me about 1 hour to

get things lined up (forwards, get out and check, backwards, get out and check,

forwards a little to the right, get out and check, etc. etc. etc.). Once I had

it centered I decided that since much of the day was now gone, I would just

level the trailer. This is when I discovered that the rear support jacks were

not robust in maintaining their length upon having weight applied to them. Ugh.. I would have to get some decent jackstands

at a later date and try to level it. I then decided to install the Sonotube/rebar extension through the hitch and pour

concrete. This went pretty well, and I got it finished by 5:00pm (at which time

I was sore and tired and felt it was a good time to wrap up for the day and

drive home). Here are some images of the

trailer (it looks a little like a trailer Darth Vader might have). Check out

the Sonotube concrete megalith through the hitch!

You can see the concrete/rebar Sonotube sticking through the

hitch A-frame, and can appreciate how this would serve to make the trailer

pretty much imobilized. I have no plans to move it at all…(in fact, it can’t be

moved).

Here are some pictures of the interior. I have about 8” of

celing height above the top of my head. I plugged in the electrical cord and

turned on the fluorescent lights. Works great!

Here

is the view from the right side window of the “V-nose”. The telescope sits

right here and can be easily monitored from inside the trailer.

Here

is an image from the access road showing the security chain across it. The

“Posted” sign is a legal notice that provides for prosecution in case of

hunting or trespassing. Such posted notices require owner name and contact

information (hence the other sign).

The

next step is to get the trailer properly leveled. Then polyurethane the inside.

Then install a desk at the front. Then….

Update 06-21-16

The

electric breaker box is positioned rather high and is in the way of where I was

planning on installing a desk (desk height is between 29-36”).

I therefore decided to move the breaker box lower on the front wall. I had to

remove the breaker box and the plywood panel for that section. Although the

screws holding the plywood panel had a Phillips head (“X”) they all seemed

stripped (i.e., did not come out when twisted with a screwdriver). Upon using a

crowbar to remove one of them it was obvious that despite the appearance of

being a screw, they had no thread to speak of (just a mild “rifling”). I pretty

much destroyed the plywood panel trying to remove it and bought another. I also

bought self-tapping 1” metal screws to reattach the new panel. I had to splice

the wires to lengthen them by about 18” in order to move the panel lower. This

necessitated marking all wires to make sure they connected back to their

original positions. In reattaching the plywood panel I could not remember

exactly where the wiring passed through the steel studs – I only hoped that I didn’t

drive one of the screws through the wiring. Upon reassembly, and reconnection

of the power, the lights turned on! So,

I guess all is ok… J

The old panel position:

Removal of breaker box and

plywood, and splicing of wiring to increase length, The

white stuff is Styrofoam insulation. The 1”x1 ½” steel studs of the frame are

visible (so is the thin aluminum skin).

Applying a new plywood panel.

Feeding the wires through a lower access hole.

The breaker box in the new

location. Note lights are on! There is room now for the planned desk top.

Update 6/29/16

I

originally planned to simply polyurethane the interior plywood. However, when

moving the breaker box I realized the trim strips of plywood at the joints of

the plywood panels was really crudely attached. Also (see above) the plywood

panels were attached in approximately 4ftx4ft sections, some with large gaps. I

decided therefore to install Luan plywood panels (the ceiling was already Luan

panels). I applied silicone caulk at the seams (and masked the edges to get

sharp lines). I also put in some trim around the door, ceiling and floor. Came

out ok, except one panel I managed to spill some glue on. Oh well…

It was really hot (~100 during

the day) so I got up at dawn to work in tolerable heat.

The installed Luan panels.

Note the two cases of Gatorade to help me survive while sweating several

gallons of precious bodily fluids.

I then caulked the panels,

installed trim molding, and applied two coats of polyurethane. You can see how the

wood color and grain emerge after polyurethane. Note also that I temporarily

removed the ceiling lights and masked windows and electrical outlets/switches.

Next

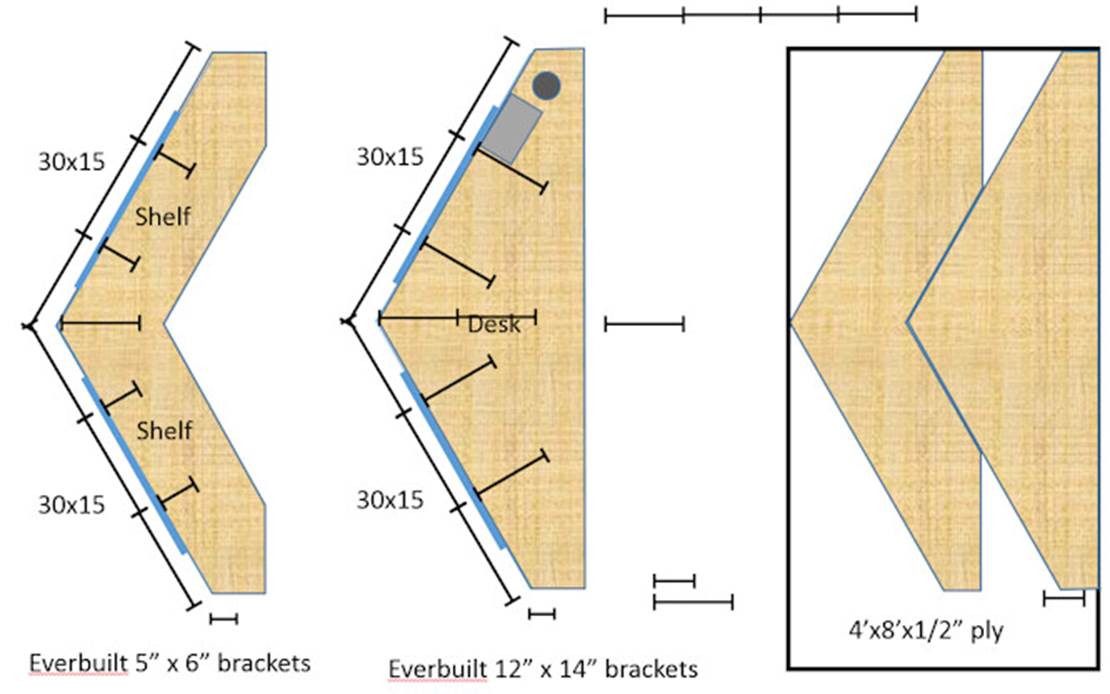

I wanted to build a desk at the front. I planned to do this using nice sanded

plywood. Such wood comes in 4ft x 8ft sheets. I originally figured I would use

one sheet of ply for the desk; however, I realized that I could also easily cut

out a shelf for above the desk:

Here’s the plywood sheet (you

can see the lines drawn out for the desktop and shelf). I could only find this

in Tallahassee (not Perry, which is 10 miles from the swamp). So I drove slowly

with this on top of the car. It was 5:30 a.m. so not much traffic!

The installed desk and shelf:

I forget to mask the caulk lines, so they look a little messy (I can go back

and maks/recaulk later).

After polyurethane application

to the desk and shelf. I originally planned to keep the floor as rough plywood.

Then I thought I would carpet or tile. However, after adding two coats of

polyurethane to the floor I kind of like the coarse wood look. I also don’t

want to spend more money, so I am leaning towards keeping the floor this way. I

have to drill a couple of holes in the desk for power/computer cords.

Update 7/4/16

I

drilled two 2” hole in the desktop for power/computer cables. I also masked and

re-caulked the desktop. I masked and caulked the baseboards. I also installed

blinds on each window (except the door). I need to order a narrower one for the

door.

Update 7/16/16

I

fine-sanded the desktop and shelf and put another coat of polyurethane on

these. I also installed 2” cable grommets in the two holes I previously drilled

in the desktop (for cables). While this was drying I installed two additional

screws in the desktop support blocks at the outer ends of the desk. I installed

a roller shade on the door. I also installed red LED lighting on the back of

the top of the shelf. Red lighting does not constrict the pupil and allows you

to see without losing night vision. I also assembled a stool (height was

perfect) and a futon. The futon fits pretty well and should let me relax on a

sofa when waiting for imaging to finish (takes up to 1 hr

for a series to complete). If I get too tired to drive back, I can now just

crash out on the futon!

Update 7/24/16

What

observatory command center is complete without a large vinyl NASA decal? (I

also sprayed the weeds today)

9/6/16 A

leak discovered just before hurricane Hermine!

Sunday

August 26 I went out to check on the observatory and make a few changes and

noticed a stain on the floor by the front door:

![]()

Clearly there was a leak, but I had not noticed it before.

However, going back over prior pictures it was apparent that there was a small

leak somewhere in the roof:

6/29/16:

7/16/16:

8/26/16:

Unfortunately, there was a hurricane due to hit is a couple

of days (Hurricane Hermine, due to land Sep 1st). The next morning

(Aug 27) I took my ladder and some roof sealing compound and took a look at the

roof above the door. There was a tiny pinhole where the factor sealant did not

cover the flashing:

I liberally smeared roof compound around it, and then

double-coated all the roof seams:

This goo requires 48hr to cure and the hurricane was due to

hit in 48hr. The hurricane knocked down a lot of trees and the power was out

for almost 4 days. Once our apartment had power and things were sorted I went

out to the swamp to check on the OCC. It appeared to have no problems at all –

in fact the inside was dry and the leak appeared to have been sealed! The power was out, but came back on 9/5. On

9/6 I went out and built some stairs out of concrete blocks (since the door is

a little high and I did not want to trip in the dark):

10/1/16

I installed some shelving in the back of the trailer for general

maintenance stuff as well as a microwave and some food items. I also installed

a broom rack on the rear door:

My daughter gave me a plaque to put up in the Command center.

The initials of the Observatory Command Center are OCC, but my family interprets

this as “Ojii-chan Care Center” (which means

“Grandfather care center” in Japanese). Somehow, this

is funny to them.

My first night in the OCC(!):

It was a clear night with no moon and excellent for imaging.

I took images of IC1805 and IC5068 nebulae:

Postscript

9/2019

Well, sad to say that I had to sell

my Observatory Command Center and swamp property. The HOA changed ownership in

2019 and the new HOA informed me they would charge me a daily fine for keeping

a trailer on my property. It was there for 3 years with no issues, but the new

HOA said they had received "complaints" about it. That seemed pretty

weird since of the 100 lots in the HOA only two have electric hookups (mine was

one), and I saw no other owner in the area since purchasing it in 2013. Almost

all the owners of record live far away (e.g. Miami) and never visit. My lot was

also the only one that was mowed regularly (others are just weed patches that

have never been mowed since 2006) and was the best maintained. There was a lot

of strange things going on with the new HOA; they elected officers before

electing board members. I took a course in Florida HOA management and submitted

my name for a board seat and was informed that they were not going to accept my

application. Their board members were selected with no vote. They also said

they were going to fine me for clear cutting my property. I sent them satellite

images from 2012 (before I purchased it) showing it was already cleared by the

prior owner (obviously they had never looked at the property since 2012). It

was all rather dubious, and the new management seemed remarkably obtuse. They

said they wanted to raise the property values. I discussed an initiative to

make the HOA a certified Dark Sky Site (which might add value at no cost since

no buildings/lighting had yet been installed); but they seemed to have never

heard of such a thing and weren't able to grasp the concept that the dark sky in

that area was a precious resource. In all fairness, the HOA docs do say you

can't have a trailer, so I couldn’t really argue it (although the HOA

management when I purchased the property was laissez faire about the trailer). Anyway, I managed to sell the trailer pretty

quickly, and sold the swamp for more than I paid for it, so I was able to

extricate myself without too much time and effort.

Back to Blaber

Observatory main page

2016 Michael Blaber